Úvod: Základ dokonalého čaju Skromné tričko je celosvetovým základom šatníka, no nie všetky tričká sú si rovné. Hlboký rozdiel medzi priemernou košeľou a košeľou, ktorá pôsobí ako druhá koža, sp...

Čítať ďalejPletené látky na mieru

information to be updated

-

-

Ako textilné inžinierstvo a odevníctvo poskytovateľ riešení, naša spoločnosť sa špecializuje na získavanie, vyhodnocovanie a dodávanie pokročilých látkových materiálov výrobcom odevov, značkám a tí...

Čítať ďalej -

1. Prečo je zmes hodvábnej bavlny inteligentnou voľbou pre špičkové košele na mieru? Snaha o dokonalú tkaninu košele často vedie ku klasickej dileme: luxusný pocit z hodvábu verzus praktické poh...

Čítať ďalej -

Skúmanie výhod žakárového mercerovaného úpletu pre citlivú pokožku Jednotlivci s citlivou pokožkou sa často snažia nájsť textílie, ktoré poskytujú pohodlie bez toho, aby spôsobovali podráždenie,...

Čítať ďalej -

Rozbaľte nadradenosť bavlneného vlákna Supima Výhoda extra dlhých sponiek: Trvanlivosť a mäkkosť Základ tejto výnimočnej textílie spočíva vo využití bavlny Supima, odrody známej pre svoj...

Čítať ďalej

How to ensure that knit apparel fabrics have uniform color and are not easy to fade during dyeing or printing?

Knit apparel fabrics are widely welcomed in the market because of their softness, breathability and good elasticity. However, knitted fabrics often face problems such as uneven color and easy fading during dyeing or printing. This not only affects the beauty of the product, but also reduces its durability. In order to overcome these challenges, it is necessary to start from multiple aspects to ensure that knitted fabrics have uniform color and are not easy to fade during dyeing or printing.

1. Optimize fabric pretreatment

The pretreatment of fabrics is the basis for ensuring the quality of dyeing or printing. First, ensure that knitted fabrics do not leave obvious traces during the weaving process, such as weft skew, weft bend, etc. These defects will be more obvious after dyeing or printing, affecting the overall appearance. Secondly, the fabric needs to be fully washed and degreased to remove impurities and oil stains on the surface to ensure that the dye can penetrate evenly.

2. Choose high-quality dyes and auxiliaries

The selection of dyes is crucial. High-quality dyes are not only bright in color, but also have good permeability and color fixation. When choosing dyes, they should be reasonably matched according to the composition and dyeing requirements of the fabric. For example, for cotton knitted fabrics, reactive dyes should be selected, while for synthetic fibers such as polyester, disperse dyes should be selected. In addition, it is necessary to add appropriate amounts of auxiliaries such as leveling agents and fixing agents to improve the uniformity and fastness of dyeing.

3. Strictly control the dyeing process

During the dyeing process, parameters such as dyeing temperature, time and pH value need to be strictly controlled. Different fabric compositions and dye types require different dyeing conditions. For example, reactive dyes are usually dyed at room temperature of about 60 degrees, while polyester needs to be dyed at a high temperature of 125-130 degrees. In addition, it is necessary to ensure that the dyeing liquid can flow into the dyeing area evenly and continuously, which can be achieved by using advanced dyeing equipment such as overflow dyeing machines. The overflow dyeing machine uses a specific design to enable the dyeing liquid to be evenly distributed on the fabric to ensure the uniformity of color.

4. Strengthen the control of printing process

For printed fabrics, in addition to selecting suitable printing slurry and dyes, it is also necessary to strengthen the control of the printing process. First of all, it is necessary to ensure the clarity and accuracy of the printed pattern to avoid blurring and dislocation. Secondly, the viscosity and fluidity of the printing paste should be controlled to ensure that the printed pattern can be evenly penetrated into the fabric fiber. Finally, sufficient drying and color fixing treatment are required to improve the fastness and durability of the printed pattern.

5. Color fixing treatment and finishing

After dyeing or printing, color fixing treatment is required to lock the color and improve color fastness. Common color fixing methods include the use of color fixing agents and heat treatment. In addition, the performance and appearance of the fabric can be further improved through finishing processes such as softening and anti-wrinkle treatment.

6. Use of advanced equipment and technology

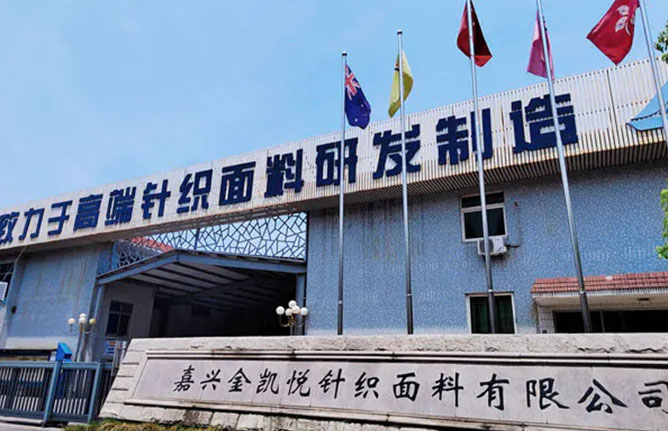

Advanced equipment and technology are one of the key factors to ensure the quality of dyeing or printing of knitted fabrics. For example, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. uses advanced circular knitting machines, which can not only create a variety of stitches for single-sided knitting and double-sided knitting, but also ensure that the fabric has better uniformity and stability during the weaving process. This lays a solid foundation for the subsequent dyeing or printing process. At the same time, the company is also equipped with advanced dyeing and printing equipment, as well as a strict quality control system, which ensures that the knitted fabrics have uniform color and are not easy to fade during the dyeing or printing process.

It takes many aspects to ensure that the knit apparel fabrics have uniform color and are not easy to fade during the dyeing or printing process. By optimizing fabric pretreatment, selecting high-quality dyes and auxiliaries, strictly controlling the dyeing process, strengthening the control of the printing process, performing color fixation and finishing, and adopting advanced equipment and technology, the dyeing or printing quality of knitted fabrics can be significantly improved to meet the market demand for high-quality knitted clothing. As a leader in the knitted fabric industry, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. has ensured its leading position in the market by continuously introducing advanced technology and equipment, as well as a strict quality control system.

Naše výrobné kapacity sú doplnené silnými výskumnými a vývojovými kapacitami, čo nám umožňuje realizovať veľké množstvo projektov s lepšou kvalitou a kratšími termínmi.

Výrobné kapacity

Silné výrobné kapacity zvyšujú vašu konkurencieschopnosť

-

Aby spoločnosť Jin Hyatt zabezpečila lepšiu kvalitu, investovala do najmodernejších strojov z Talianska, Nemecka, Švajčiarska, Japonska a Taiwanu.

-

Spoločnosť sa zaoberá najmä rôznymi materiálmi vrátane morušového hodvábu, bavlny s tekutým amoniakom, vlny, kašmíru, športových látok a rôznych zmesí vlákien.

-

Spoločnosť efektívne riadi skladovanie surovín a hotových výrobkov, integruje celý výrobný proces a zlepšuje celkovú efektivitu.

-

Spoločnosť sa zameriava na trh s vysoko kvalitnými pletenými látkami a venuje 20 % svojej pracovnej sily výskumu a vývoju s cieľom zvýšiť hodnotu produktov a konkurencieschopnosť.

中文简体

中文简体