Úvod: Základ dokonalého čaju Skromné tričko je celosvetovým základom šatníka, no nie všetky tričká sú si rovné. Hlboký rozdiel medzi priemernou košeľou a košeľou, ktorá pôsobí ako druhá koža, sp...

Čítať ďalejzvyk Vlny nylonové tkaniny

Wool nylon fabric is the preferred material in the high-end textile field, combining the natural warmth of wool with the durability of nylon. The fabric is selected from high-quality wool fibers to retain its good warmth and breathability and is blended with high-strength nylon fibers to significantly enhance the fabric's tear resistance and wear resistance, ensuring morphological stability and durability for long-term use. Wool nylon fabric also has good moisture absorption and perspiration functions, which can effectively regulate body surface humidity and keep you dry and comfortable. It is suitable for various intensity activities. Its fiber structure is delicate, color expression is strong, dyeing is stable, and it meets personalized and fashion needs. This fabric is suitable for all seasons and is widely used in high-end ready-to-wear, sports and leisure wear, home decoration, and other fields, showing extraordinary visual texture and high-end quality. Wool nylon fabric, with its unique material combination and good performance, has become an ideal choice for consumers who pursue a high-quality life, reflecting the good combination of textile technology and natural materials.

-

-

Ako textilné inžinierstvo a odevníctvo poskytovateľ riešení, naša spoločnosť sa špecializuje na získavanie, vyhodnocovanie a dodávanie pokročilých látkových materiálov výrobcom odevov, značkám a tí...

Čítať ďalej -

1. Prečo je zmes hodvábnej bavlny inteligentnou voľbou pre špičkové košele na mieru? Snaha o dokonalú tkaninu košele často vedie ku klasickej dileme: luxusný pocit z hodvábu verzus praktické poh...

Čítať ďalej -

Skúmanie výhod žakárového mercerovaného úpletu pre citlivú pokožku Jednotlivci s citlivou pokožkou sa často snažia nájsť textílie, ktoré poskytujú pohodlie bez toho, aby spôsobovali podráždenie,...

Čítať ďalej -

Rozbaľte nadradenosť bavlneného vlákna Supima Výhoda extra dlhých sponiek: Trvanlivosť a mäkkosť Základ tejto výnimočnej textílie spočíva vo využití bavlny Supima, odrody známej pre svoj...

Čítať ďalej

For woolen nylon fabrics, are shrinking and raising processes performed? What effects do these processes have on fabric performance?

Shrinkage is an important step in the textile production process, which aims to reduce the dimensional changes of fabrics during use or washing through pretreatment. Shrinkage is also important for wool nylon fabrics.

Shrinkage usually involves pre-shrinking the fabric, that is, making the fabric undergo dimensional changes similar to those in actual wearing and washing under certain temperature and humidity conditions. This process helps stabilize the size of the fabric and reduce the shrinkage rate in subsequent use. During the shrinkage process, the fabric will undergo specific mechanical or chemical treatments to ensure that its fiber structure is more compact, thereby reducing the tendency to shrink.

Impact of shrinkage on fabric performance

Improved dimensional stability: After shrinkage, the dimensional stability of wool nylon fabrics is significantly improved, reducing dimensional changes during actual wearing and washing, thereby extending the service life of the garment and maintaining a good version.

Strengthened fiber structure: During the shrinkage process, the interaction between fabric fibers is enhanced, making the fabric stronger and more durable. This strengthening effect helps to improve the fabric's tear and abrasion resistance.

Improved wearing comfort: Stable size means that the fabric is not easy to deform during wearing, thus maintaining a good fit and comfort. In addition, shrinking can also help reduce wrinkles after washing, making the garment smoother and more beautiful.

However, it is worth noting that shrinking can also have a negative impact on certain properties of the fabric. For example, excessive shrinking may cause the fabric to feel harder or lose gloss. Therefore, the treatment conditions need to be strictly controlled during the shrinking process to ensure that the dimensional stability of the fabric is maintained without compromising its other properties.

Raising is a common method for textile surface finishing, which aims to form a layer of fine fluff on the surface of the fabric through mechanical or chemical means, thereby improving the softness, warmth and touch of the fabric. For wool-spun nylon fabrics, raising is also important.

Raising usually involves rubbing the fabric with a raising machine to remove fiber hair on the surface of the fabric and form fluff at the ends of the fibers. During this process, the brushing part of the raising machine will repeatedly rub the fabric until the desired fluff effect is achieved. In addition, the fluff can be further fixed by chemical treatment or heat pressing to improve the durability of the fabric.

Effect of raising process on fabric performance

Softness improvement: After raising process, a layer of fine fluff is formed on the surface of the fabric, making the fabric softer and more comfortable. This soft touch helps to improve the comfort of the wearer.

Warmth improvement: The presence of the fluff layer increases the thickness of the air layer inside the fabric, thereby improving the warmth retention of the fabric. This is especially important for winter clothing and home decoration products.

Improved touch: The raising process makes the surface of the fabric more delicate and smooth, reducing the irritation of the fiber hairiness to the skin. This improvement helps to improve the overall wearing experience of the wearer.

However, raising process may also bring some potential problems. For example, excessive raising process may cause excessive and thick fluff on the surface of the fabric, affecting the breathability and appearance of the fabric. In addition, the fluff layer may also become a hiding place for dirt and bacteria, increasing the difficulty of cleaning. Therefore, the degree and time of treatment need to be strictly controlled during the raising process to ensure that the softness and warmth retention of the fabric are maintained without compromising its breathability and cleanliness.

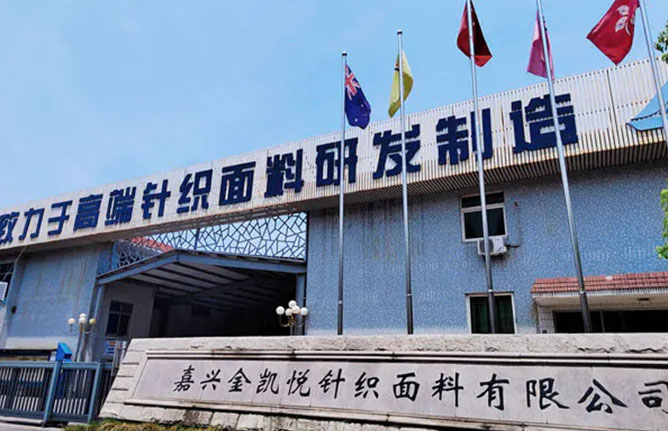

As an enterprise focusing on the production of high-end knitted fabrics, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. has accumulated rich experience in the shrinkage and raising processing of wool nylon fabrics. With advanced circular knitting machines and technologies, it is able to produce a variety of knitted fabrics, including complex structures such as flat needles, rib needles, and jacquard needles. To ensure product quality and performance stability, the company has introduced advanced equipment and technical means from Italy, Germany, Switzerland, Japan and other places.

In terms of shrinkage processing, the company strictly controls the processing conditions and time to ensure that the fabric maintains dimensional stability while not compromising its softness and breathability. It also conducts strict dimensional stability tests on the shrunken fabrics through advanced testing equipment to ensure that the products meet customer requirements.

In terms of raising processing, the company focuses on maintaining the fine and smooth surface of the fabric and the uniform distribution of the fluff layer. Advanced raising machines and brushing parts are used to perform fine raising treatment on the fabric. The fluff layer is further fixed by chemical treatment or hot pressing to improve the durability and cleanliness of the fabric.

Naše výrobné kapacity sú doplnené silnými výskumnými a vývojovými kapacitami, čo nám umožňuje realizovať veľké množstvo projektov s lepšou kvalitou a kratšími termínmi.

Výrobné kapacity

Silné výrobné kapacity zvyšujú vašu konkurencieschopnosť

-

Aby spoločnosť Jin Hyatt zabezpečila lepšiu kvalitu, investovala do najmodernejších strojov z Talianska, Nemecka, Švajčiarska, Japonska a Taiwanu.

-

Spoločnosť sa zaoberá najmä rôznymi materiálmi vrátane morušového hodvábu, bavlny s tekutým amoniakom, vlny, kašmíru, športových látok a rôznych zmesí vlákien.

-

Spoločnosť efektívne riadi skladovanie surovín a hotových výrobkov, integruje celý výrobný proces a zlepšuje celkovú efektivitu.

-

Spoločnosť sa zameriava na trh s vysoko kvalitnými pletenými látkami a venuje 20 % svojej pracovnej sily výskumu a vývoju s cieľom zvýšiť hodnotu produktov a konkurencieschopnosť.

中文简体

中文简体